3red street light rail – phase 02 – China Town Station (CTS)

San Francisco, California.

(Rebar Detailing)

The total estimated weight for this job is 3,000+ tons. We received the job in February 2014, and the construction duration, involving rebar and concrete, spanned from 2014 to 2020. Throughout this period, we maintained extensive communication with the rebar supplier.

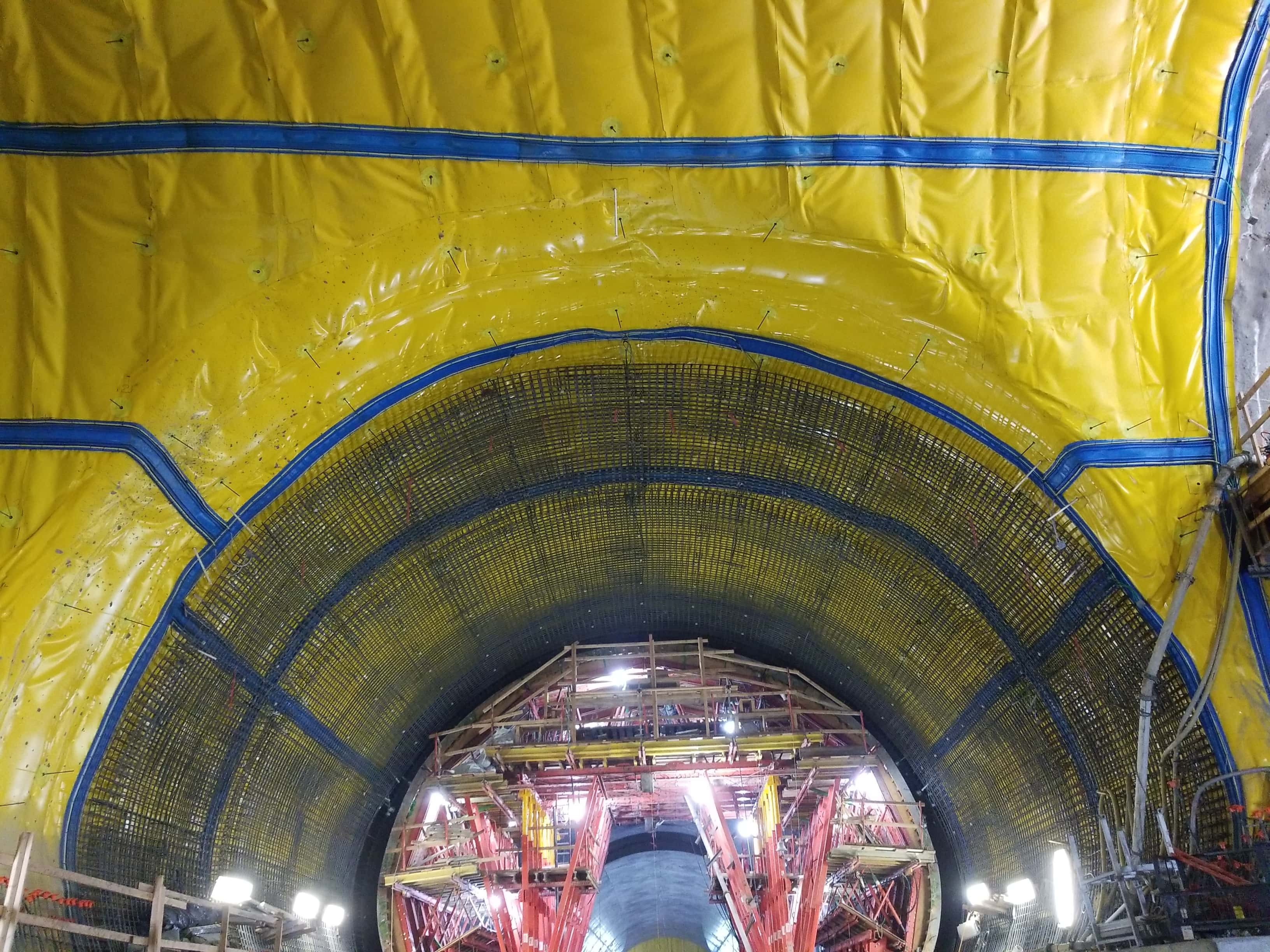

We received 800+ Requests for Information (RFIs) related to the redesign of structural details. We incorporated and sent the shop drawings in a timely manner. The structural and profile design for this job was artful and crafty. The project consisted of two structures: 1) the head house and 2) the cavern. The head house comprised 8 floors below ground level, and the cavern structure was connected with the lowest 3 levels. The cavern structure was divided into Platform Cavern, Crossover Cavern, Headwall, and Emergency Egress.

Most of the head house structural elements were reinforced with end preparation for mechanical splice and end anchorage purposes. The reinforcement area was high for each structural element, leading to higher rebar congestion. However, we identified and presented all rebar congestions and conflicts to the customer through 2D shop drawings (without using Tekla). Based on this information, the field team took necessary actions in advance to avoid conflicts during bar placement. As a result, the customer saved a considerable amount on materials and labour costs.

The profiles of all structures, including Platform Cavern, Crossover Cavern, Crosscut Cavern, Headwall, and Emergency Egress, were extremely artful, featuring irregular arc shapes and varying dimensions. Although detailing such structures is typically done in 3D/Tekla software, we utilized Rebar CAD 2D software only. We issued sufficient sections, elevations, and plan details with clear bar arrangements from all four directional views, making it easy to understand the placement. We received appreciation from the field multiple times for our drawing preparation methods.